All New Ships Should Be Built To a Seawater-Lubricated Sterntubeless Ship Design, Says Leontopolous

Exploring the Advantages of Lubricated Sterntubeless Systems

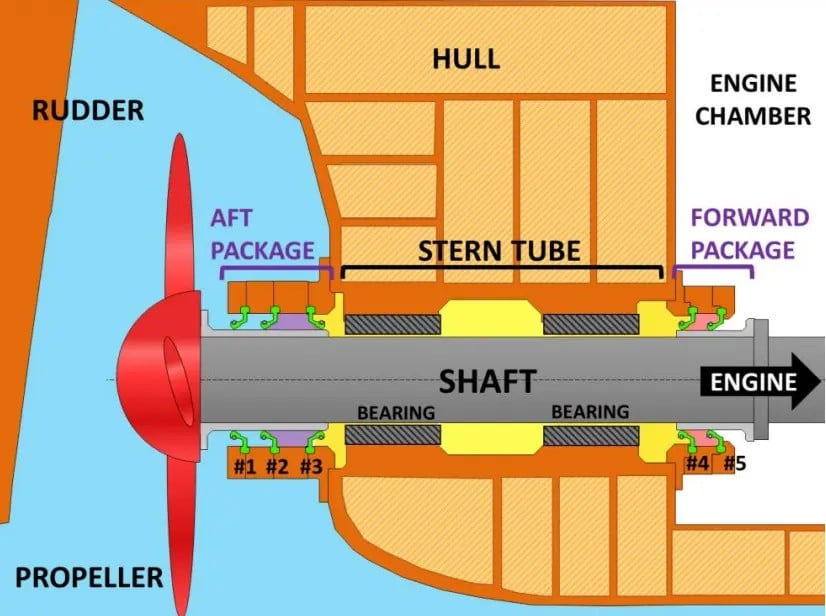

According to Chris Leontopoulos of Blue Ocean Alliance, future newbuild ships should adopt a sterntubeless design featuring seawater-lubricated propeller shaft bearings.

Mr. Leontopoulos highlighted the environmental impact of over eight million liters of sterntube lubricating oil polluting the oceans annually. He asserted that eliminating the sterntube, shortening the propeller shaft, and moving the prime mover further aft would reduce friction, improve fuel efficiency, lower emissions, and create more cargo space without altering hull lines or class regulations.

The sterntubeless design features a seawater-lubricated bearing, eliminating the need for aft seals and shaft coating systems. This results in reduced maintenance costs, less downtime, and extended operational capabilities. The design also incorporates a dry internal inspection chamber, allowing maintenance of propeller shaft components while the ship remains operational.

Leontopoulos acknowledged that while the initial CAPEX might increase by $10,000 to $30,000, the ROI is swift due to significantly reduced operational expenditures. Operators could save over $1 million in lifetime operational costs, with immediate savings from reduced lubricating oil consumption, lower fuel costs, decreased drydocking, and maintenance expenses, as well as increased cargo capacity.

He noted that ABS has published a guide on sterntubeless vessels and introduced a new notation for the design, awarded an AiP in June 2022. Neil McDonald of Thordon Bearings praised the design as a milestone in shipping, emphasizing its environmental and operational sustainability without the need for new class rules.

Leontopoulos concluded that the first sterntubeless ship with a Thordon seawater-lubricated propeller shaft bearing system is expected to be ordered within the next twelve months, likely based on an SDARI design.