Kongsberg Maritime Secures Significant Contract for Golar Mk2 FLNG Vessel

Kongsberg Maritime Secures Major FLNG Contract

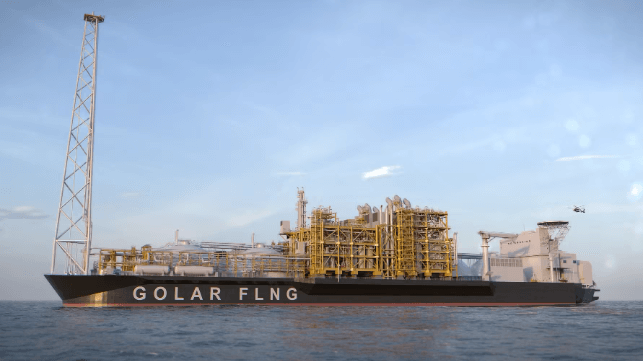

Kongsberg Maritime has recently announced a significant contract that will enhance the liquefied natural gas (LNG) industry. The company will provide an integrated package of electrical, control, safety, and propulsion systems for the Golar Mk2 Floating Liquefied Natural Gas (FLNG) project. Valued at over $25 million USD, this contract marks a pivotal step in the conversion of the Fuji LNG tanker into a state-of-the-art FLNG vessel. The project is currently underway at the CIMC Raffles shipyard in Yantai, China, and is expected to revolutionize the way LNG is processed and transported.

Transforming the Fuji LNG Tanker

The Golar Mk2 project involves a major rebuild of the Fuji LNG tanker, which will be lengthened by nearly 100 meters. This transformation will convert the vessel into a floating liquefaction plant, capable of processing natural gas in offshore and remote locations. The innovative FLNG technology eliminates the need for permanent infrastructure, such as pipelines and onshore facilities, making it a more flexible and cost-effective solution for gas extraction. Once gas reserves are depleted, FLNG units can be redeployed to other fields, enhancing their economic viability.

GTT signs a service contract for ENI’s Coral Sul FLNG in Mozambique

Kongsberg Maritime’s contribution to this project includes advanced equipment such as two UUC305 azimuth thrusters and an integrated control and safety system (ICSS). The thrusters will feature a Heading Control system, which utilizes Kongsberg’s expertise in Dynamic Positioning (DP) without requiring full DP capabilities. This integration ensures that the FLNG unit operates safely and efficiently, even in challenging offshore environments.

Ensuring Safety and Efficiency

The ICSS provided by Kongsberg Maritime is a comprehensive solution designed to ensure the safe and efficient operation of the FLNG unit. It integrates various systems, including energy management, power distribution, cargo handling, ballast control, and auxiliary systems. Safety is a top priority, and the ICSS includes critical components such as the Emergency Shutdown System (ESD), Fire and Gas Detection System (F&G), and Process Shutdown System (PSD). These systems work together to provide robust protection and maintain operational integrity throughout the vessel’s lifecycle.

Morten Skjong, Golar LNG’s Project Manager for the MK II FLNG, expressed confidence in Kongsberg Maritime’s capabilities, stating that the company has been a trusted supplier for decades. He emphasized the importance of quality solutions for the long-term success of their operations. Lisa Edvardsen Haugan, President of Kongsberg Maritime, echoed this sentiment, highlighting the company’s commitment to supporting Golar LNG’s innovative conversion project. With a collaborative approach involving CIMC Raffles and Black & Veatch, Kongsberg Maritime aims to ensure seamless integration of systems during this complex conversion process.

As the demand for LNG continues to grow globally, the Golar Mk2 FLNG project represents a significant advancement in the industry. Kongsberg Maritime’s expertise and innovative technology will play a crucial role in shaping the future of floating LNG production.