Wärtsilä’s Innovative Steps Towards Decarbonisation

Wärtsilä Propulsion Package to Power Largest Methanol Cement Carrier Vessel

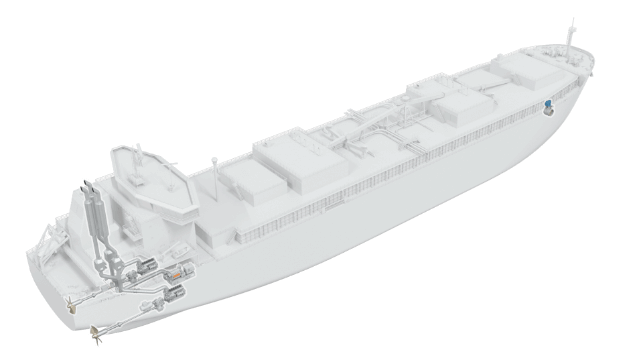

Wärtsilä, a leading technology group, is making significant strides in supporting the marine industry’s efforts to reduce carbon emissions. The company has recently secured an order to supply a complete propulsion package for a groundbreaking vessel—a 38,000 DWT methanol-ready cement carrier. This vessel will not only be the largest of its kind but also the first to have a methanol-ready notation. The order comes from NovaAlgoma, a joint venture between Nova Marine Group and Algoma Central Corporation. The ship will be constructed at Zhejiang Xinle Shipbuilding Co., Ltd., with plans for its launch in late 2026. This order was officially recorded by Wärtsilä in the fourth quarter of 2024, marking a significant milestone in the company’s commitment to sustainability in maritime operations.

Innovative Design for a Sustainable Future

The new cement carrier represents a pivotal shift in the maritime industry towards eco-friendly operations. According to Vincenzo Romeo, CEO of Nova Marine Group, this vessel is a testament to their fleet development strategy. It aims to meet the growing demand for cement while prioritizing environmental sustainability. Romeo emphasizes that this will be the largest and most environmentally friendly cement carrier ever built. The collaboration with Wärtsilä as the technology provider is crucial for achieving their decarbonisation goals. This partnership highlights the importance of innovation in the marine sector, especially as global pressure mounts to reduce carbon footprints.

LR to class Vard built methanol-ready Commissioning Service Operations Vessels

The Wärtsilä propulsion package includes advanced technology designed to enhance efficiency and reduce emissions. The package features two Wärtsilä 32 engines and one Wärtsilä 25 auxiliary engine, among other components. These engines are engineered for optimal performance and easy maintenance, ensuring long operational periods without the need for extensive servicing. The Wärtsilä 32 engine is particularly noteworthy for its fuel flexibility, allowing for a seamless transition to methanol as a fuel source. This capability is essential for meeting future regulatory requirements and environmental standards.

Holistic Approach to Decarbonisation

Wärtsilä’s commitment to decarbonisation is evident in its holistic approach to the design and operation of the new vessel. Roger Holm, President of Wärtsilä Marine, underscores the shared commitment between Nova and Wärtsilä to minimize emissions in shipping operations. The integrated propulsion package is designed to optimize energy use during operations, aligning with Nova’s sustainability objectives. This collaboration is not just about building a ship; it’s about creating a model for future vessels that prioritize environmental responsibility.

The propulsion solutions provided by Wärtsilä are engineered for high efficiency. They include gearboxes that reduce propeller speed, allowing for a larger propeller diameter. This design maximizes propulsive efficiency, which is crucial for meeting compliance targets in an increasingly regulated industry. The inclusion of selective catalytic reduction (SCR) exhaust after-treatment systems further enhances the vessel’s ability to minimize harmful emissions. As the maritime industry faces growing scrutiny over its environmental impact, innovations like these are essential for ensuring a sustainable future.