HD Hyundai exports HiMSEN engines to 60 countries

South Korea's Shipbuilding Industry Shines Bright

As the political landscape in the United States shifts with the impending announcement of tariffs by President Donald Trump, South Korea faces its own set of challenges. The ongoing impeachment proceedings against the President and Acting President create uncertainty for the South Korean economy. Despite these turbulent times, South Korean corporations, equipped with cutting-edge technology, continue to make significant strides on the global stage. One shining example is HD Hyundai Heavy Industries, a leader in the shipbuilding sector. This article delves into the remarkable achievements of this company and its contributions to the global maritime industry.

A Glimpse into HD Hyundai Heavy Industries

On a recent visit to the HD Hyundai Heavy Industries Ulsan Shipyard in Dong-gu, Ulsan, the scale of operations was impressive. All ten docks were bustling with activity, filled with ships under construction. This shipyard has the capacity to produce up to 50 ships annually. The largest dock, comparable in size to nine soccer fields, was simultaneously hosting the construction of four liquefied natural gas (LNG) and liquefied petroleum gas (LPG) carriers, each measuring up to 300 meters in length.

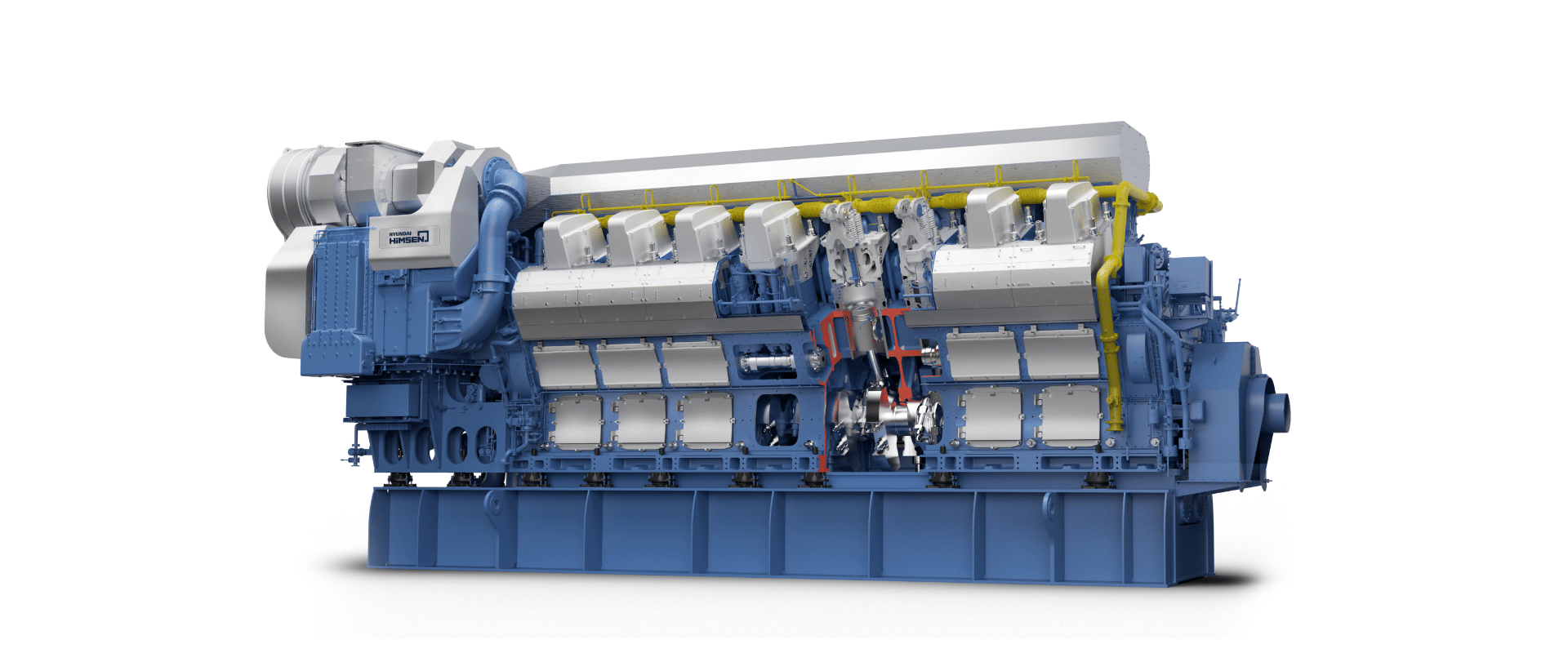

The heart of these ships lies in their engines. At the shipyard’s powerful engine plant, dozens of HiMSEN Engines were lined up, each weighing up to 90 tons and standing between 3.5 to 4 meters tall. Developed independently by HD Hyundai Heavy Industries after over a decade of research, the HiMSEN Engine was first introduced in South Korea in 2000. These medium-speed engines play a crucial role in generating electricity within the ships, while larger engines drive the ship’s propellers. Typically, a single ship is equipped with one large engine, measuring 13 meters high, and several medium engines for power generation.

HD Hyundai Heavy Industries has achieved a remarkable feat by independently developing medium-speed engines, a technology that only three other countries—Finland, Germany, and Japan—have successfully mastered over a century. The company has established a significant presence in the global market, exporting to over 60 countries and capturing approximately 35% of the medium-speed engine market share. This success story highlights the company’s innovative spirit and commitment to excellence in a highly competitive industry.

Innovation and Technological Advancements

The shipbuilding market is known for its conservative nature, with customers often relying on established companies for their engine needs. However, HD Hyundai Heavy Industries has managed to build trust with its clients by demonstrating a commitment to resolving any issues that arise, regardless of time and cost. Yu, the Executive Director of the Quality and Planning Division, emphasized the importance of customer trust in a market where new entrants face significant challenges.

During a recent factory visit, workers were seen meticulously inspecting the connections between the elongated yellow pipes and the HiMSEN Engine’s main body. These pipes are responsible for supplying gas fuel to the engine, and ensuring there are no gaps is critical to preventing gas leaks. Currently, 60% of the HiMSEN Engine production consists of dual fuel (DF) engines, which can utilize traditional ship fuels like bunker oil alongside LNG and methanol. This innovative approach has made dual fuel engines the mainstream choice, accounting for 60 to 70% of new ship constructions.

CCS Completed Survey for Retrofitting of Methanol Dual Fuel Engine to first operating vessel

In 2008, HD Hyundai Heavy Industries took a bold step by venturing into gas engine development, a move that few had anticipated. This led to the creation of the dual fuel HiMSEN Engine, capable of using both diesel and LNG. The development process required advanced management technology to store LNG at ultra-low temperatures. In collaboration with Germany’s MAN, the company became the first globally to develop a dual fuel large engine using LNG, showcasing its commitment to innovation and sustainability.

Commitment to Sustainability and Future Growth

HD Hyundai Heavy Industries is not only focused on production but also on sustainability. In October of last year, the company made headlines by developing the world’s first high-pressure direct-injection HiMSEN ammonia dual fuel engine (H22CDF-LA). This engine represents a significant advancement in technology, as it enhances output and fuel efficiency while reducing greenhouse gas emissions. The high-pressure direct injection method poses technical challenges, but the company has successfully optimized fuel injection timing and redesigned components to improve combustion efficiency.

Most components of the HiMSEN Engine are sourced domestically, underscoring the company’s commitment to supporting local industries. The assembly process involves around 300 workers, who produce approximately 1,000 engines annually across three factories. The production process is efficient, with each engine taking about four weeks to manufacture, followed by a week of internal testing before the shipowner’s inspection.

The HiMSEN Engine is versatile, finding applications not only in maritime settings but also in onshore power generation. In 2005, the company supplied 588 land power generation facilities equipped with HiMSEN Engines throughout Cuba, showcasing the engine’s reliability and efficiency. The recognition of the HiMSEN engine land power station on Cuba’s 10 pesos bill reflects its significance in the country’s energy revolution.