ClassNK issues Approval in Principle (AiP) for large liquefied CO2 carriers of 50,000 m³ and 23,000 m³

Working towards ensuring stable supply of liquefied CO2 carriers for support of CCS projects

New Design for Large CO2 Carriers Approved to Help Reduce Emissions

A group of big companies, including Mitsui & Co., Kawasaki Kisen Kaisha, and Mitsubishi Shipbuilding, has developed new designs for ships that can carry large amounts of liquefied carbon dioxide (CO2). These special ships are important because they will help with projects to capture and store CO2. This is a process known as Carbon Dioxide Capture and Storage (CCS). By capturing CO2 and transporting it to safe storage places, we can reduce harmful emissions in the air.

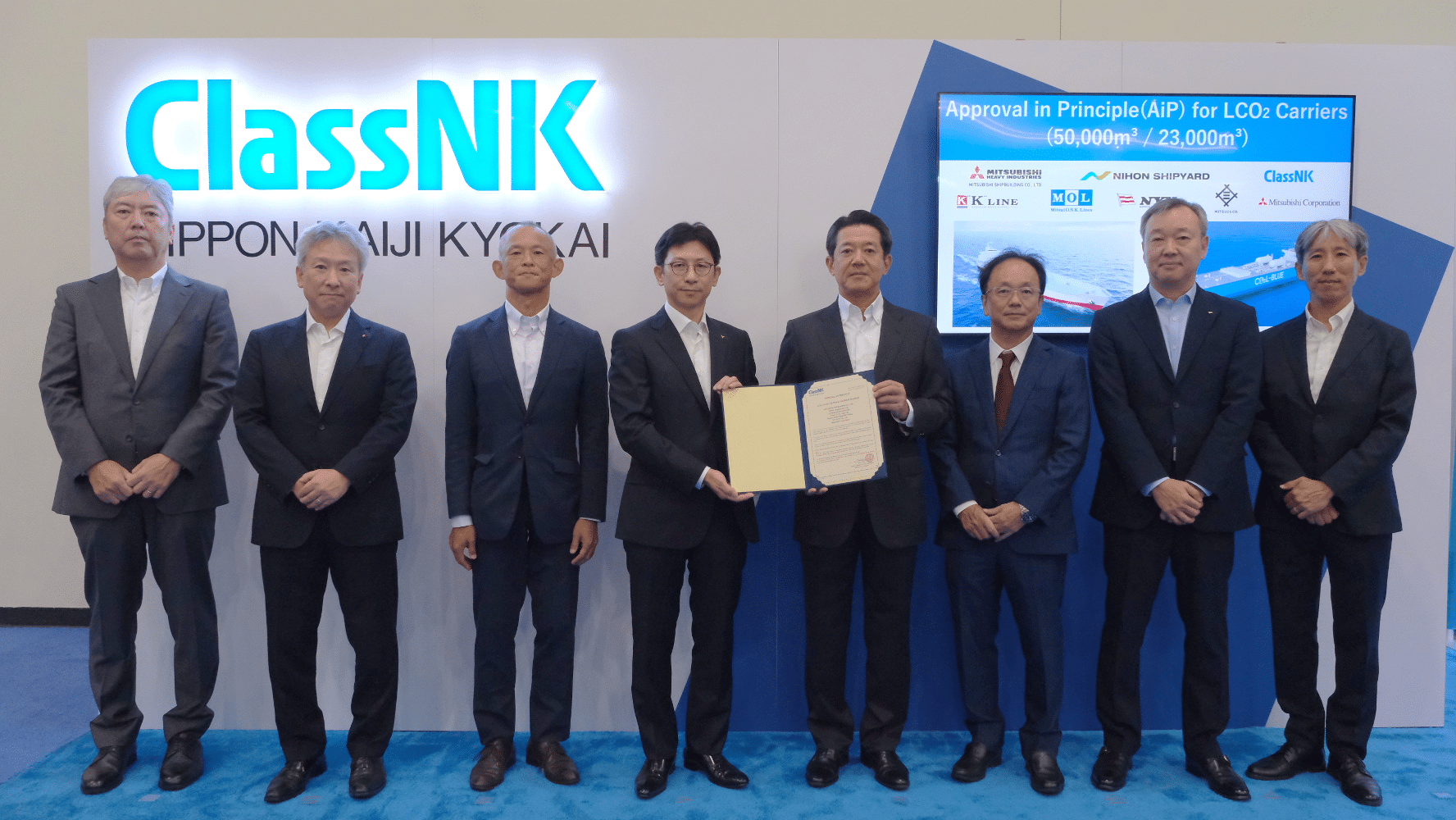

The companies’ new design has been approved by ClassNK, a major organization that checks and certifies ship safety. ClassNK gave them an Approval in Principle (AiP), meaning the designs follow the rules and are safe for building. These new ships come in two sizes, one that can carry 50,000 m³ of CO2 and a smaller one that can carry 23,000 m³.

US Coast Guard Formally Approves ABS Wavesight™ eLogs for U.S.-Flagged Ships

What Does This Approval Mean?

The approval given by ClassNK is very important. As more projects focus on capturing CO2 to fight climate change, we will need many ships to transport the gas safely. The new design is an important step because it helps standardize how these ships should be built. This means that when more companies want to build CO2 carriers, they can follow this design, making the whole process faster and easier.

The handover ceremony of the AiP certificate took place at the “Gastech 2024” event in Houston, USA. Many big names in shipping and engineering attended the event, showing their support for this new design.

How Was the Design Reviewed?

ClassNK looked at the ship designs carefully using a set of rules made for steel ships that carry liquefied gases, like CO2 and LNG. These rules, known as the IGC Code, make sure the ships are safe for carrying dangerous gases. ClassNK checked that the designs meet all these rules, and after everything was confirmed, they gave the approval.

The new ships will also use a special method to build the tanks that hold the CO2. This method, called Engineering Critical Assessment (ECA), will make the tank-building process faster and safer. Usually, when large tanks are built, they need to go through a process called Post Weld Heat Treatment (PWHT), which uses high heat to make sure the tanks are strong and safe. This new method could help skip this step, making it easier to build these large CO2 tanks.

What’s Next for CO2 Carriers?

With more companies focusing on capturing and storing CO2, the demand for these new ships will grow. ClassNK plans to keep working on ways to make ship designs even better and safer. By helping with new designs like these, they are supporting the global effort to reduce emissions and fight climate change.

These large CO2 carriers will be a big part of the future as the world looks for better ways to protect the environment. Reducing the amount of carbon dioxide in the air is a crucial step in slowing down global warming, and these ships will help make that possible by safely transporting CO2 to storage areas deep underground.

With the support of major companies like Mitsubishi, Mitsui, and Kawasaki, this new ship design is set to become an important part of the fight for a cleaner and greener world.