OCIMF Mooring Equipment Guidelines (MEG4): Term Definition

The Oil Companies International Marine Forum (OCIMF) has established comprehensive guidelines for Mooring System Management Plans (MSMP) to enhance the safety and efficiency of mooring operations. These guidelines are a crucial component of the Mooring Equipment Guidelines, Fourth Edition (MEG4), which provide a framework for managing mooring systems from design to retirement.

The MSMP includes detailed lists of mooring equipment, inspection, maintenance, and retirement strategies, as well as risk and change management principles. It also emphasizes the safety of personnel and the importance of human factors in mooring operations.

The MSMP Register, a subset of the MSMP, along with the Line Management Plan (LMP), assists ship operators in documenting and managing their mooring equipment effectively. This guidance is further supported by the Vessel Inspection Questionnaire (VIQ7), which integrates the planning procedures into its inspection process. By adhering to these guidelines, ship designers, terminal designers, ship operators, and mooring line manufacturers can significantly improve the design, performance, and safety of mooring systems.

What is the MSMP?

The MSMP should contain the following:

- Part A – General ship particulars

- Part B – Mooring equipment design philosophy

- Part C – Detailed list of mooring equipment

- Part D – Inspection, maintenance and retirement strategies

- Part E – Risk and change management, safety of personnel, and human factors

- Part F – Records and documentation

- Part G – Mooring System Management Plan Register (MSMPR)

The MSMP should be kept on board at all time, and should be available for vetting inspection.

Term Definition

There are numerous terms used in the Mooring Equipment Guidelines, Fourth Edition (MEG4). Lets have a look at these terms:

Ship Design Minimum Breaking Load

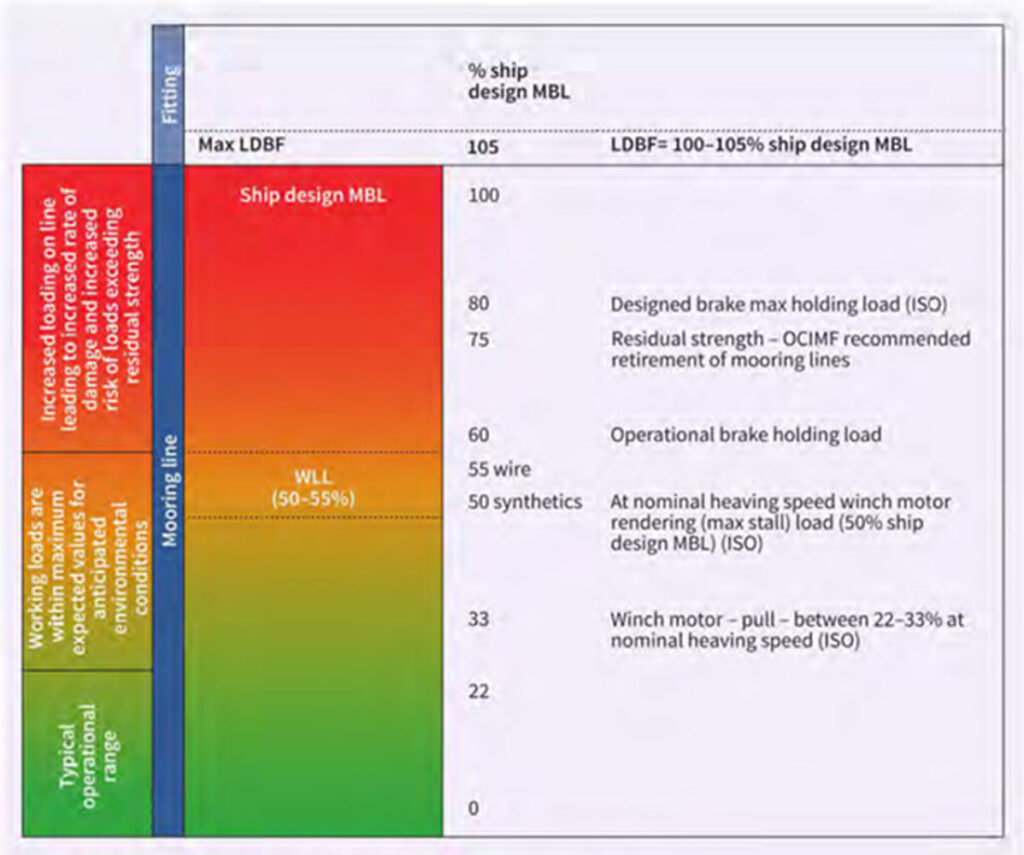

The concept of Minimum Breaking Load (MBL) is crucial in the design of ship mooring systems. As per the Mooring Equipment Guidelines Fourth Edition (MEG4), the Ship Design MBL refers to the minimum breaking load for which a ship’s mooring system is designed, ensuring it meets the standard environmental criteria restraint requirements. This parameter is fundamental as it determines the sizing and design of all other components within the ship’s mooring system.

Line Design Break Force (LDBF)

MEG4 has introduced new terminology and guidelines to clarify the confusion that previously existed between line users and manufacturers regarding MBL. For instance, the Line Design Break Force (LDBF) is now defined as the minimum force at which a new, dry, spliced mooring line will break when tested, which should be 100-105% of the Ship Design MBL.

Working Load Limit (WLL)

Additionally, the Working Load Limit (WLL) is the maximum load that a mooring line should be subjected to during operational service, calculated from the standard environmental criteria and expressed as a percentage of the Ship Design MBL. These guidelines ensure that the mooring lines are not only designed with safety margins but also used within safe operational limits to prevent accidents and equipment failure. Understanding and implementing these guidelines is essential for the safety and efficiency of mooring operations in the maritime industry. OCIMF recommends a Working Load Limit (WLL) 60% of ship design MBL.

Winch Brake Design Load

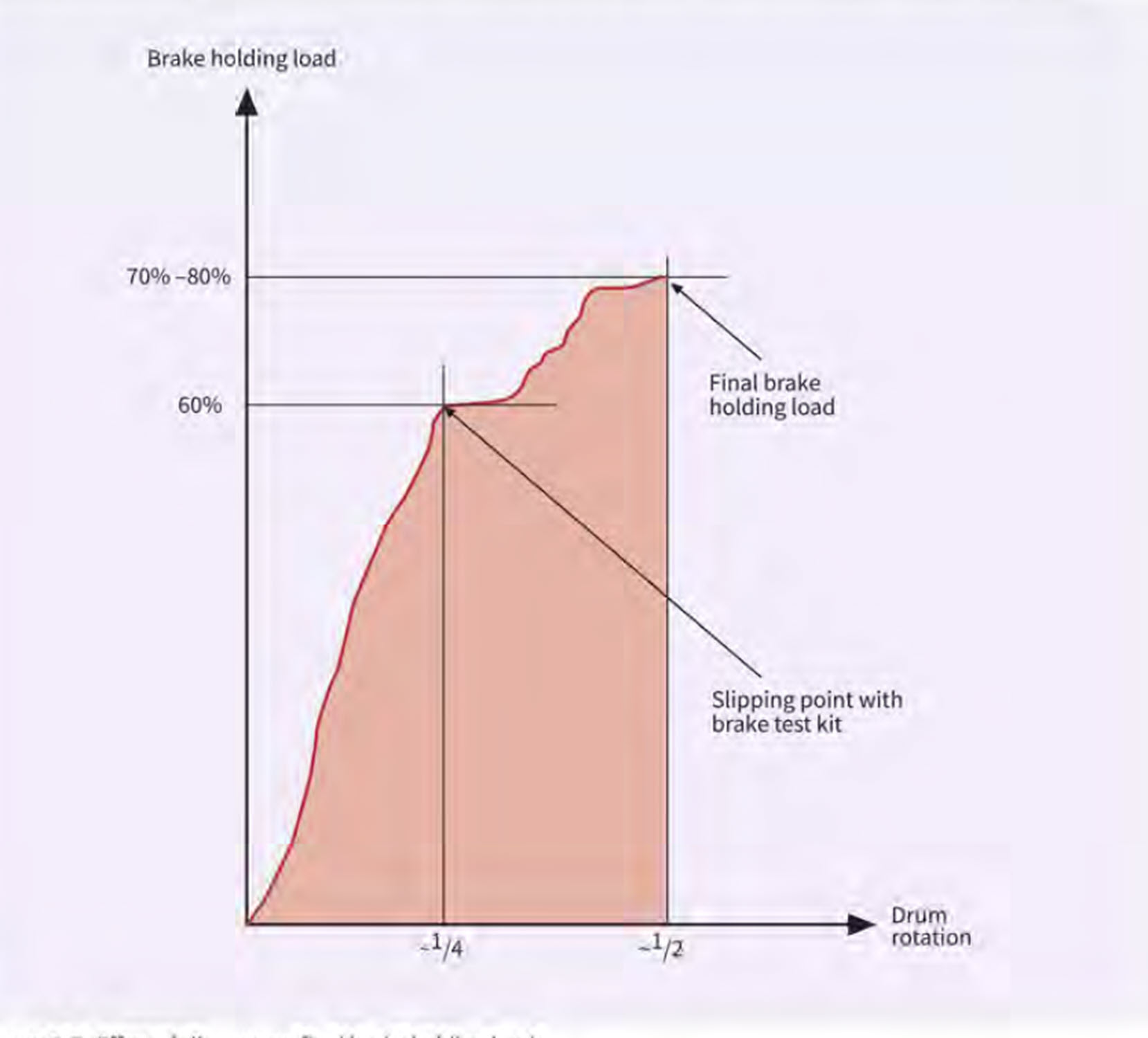

OCIMF recommends a Brake Design Load 80% of ship design MBL. This is because brakes may deteriorate from wear and tear in service, so it is recommended that new equipment be designed to hold 80% of the ship design MBL, but have the capability to be adjusted down to 60% of the ship design MBL to meet the OCIMF recommendation.

Winch Brake Holding load/Winch Motor Render Load

OCIMF recommends a brake holding load setting of 60% of ship design MBL, on the first layer instead of the 80% value in ISO 3730. It is also called Operational brake holding load. The brake should have the capability to be set up to the 80% value, to always allow a setting at 60% to be achieved irrespective of wear and tear on the brake.

Winch Pull Load

The concept of winch pull load is a critical aspect in the Mooring Equipment Guidelines, Fourth Edition (MEG4), which provides comprehensive guidance on the safe mooring of vessels. OCIMF recommends a Winch Pull Load of 22-33% of ship design MBL at nominal heaving speed.

Maximum Ship Design MBL

The Maximum Breaking Load (MBL) in the context of Mooring Equipment Guidelines 4th edition (MEG4) is a critical factor in the design and operation of mooring systems. Mooring Structural Safe Working Load should be in range of 100% of ship design MBL.

Specified Minimum Yield Stress (SMYS)

Specified Minimum Yield Stress (SMYS) is a critical parameter in the engineering and construction of pipelines, particularly in the oil and gas industry. It represents the minimum stress that a material, typically steel, can withstand without undergoing permanent deformation.

Line Management Plan (LMP)

LMP is used to manage the operation and retirement of mooring lines and tails. The LMP also documents the requirements, assumptions and evaluation methods used in determining the line retirement criteria. The LMP is specific to an operator, ship type, and trade route; however, MEG4 gives general guidance on establishing a LMP.

Mooring System Management Plan (MSMP)

The MSMP is to be ship specific and complement the ship’s safety management system. Through a ‘goal-based’ approach, core elements of the mooring system are identified against which high level ‘goals’ are established supported by more detailed ‘functional requirements’. A register of the mooring system components is maintained for the ship’s life in an accompanying Mooring System Management Plan Register (MSMPR).