Riviera – News Content Hub

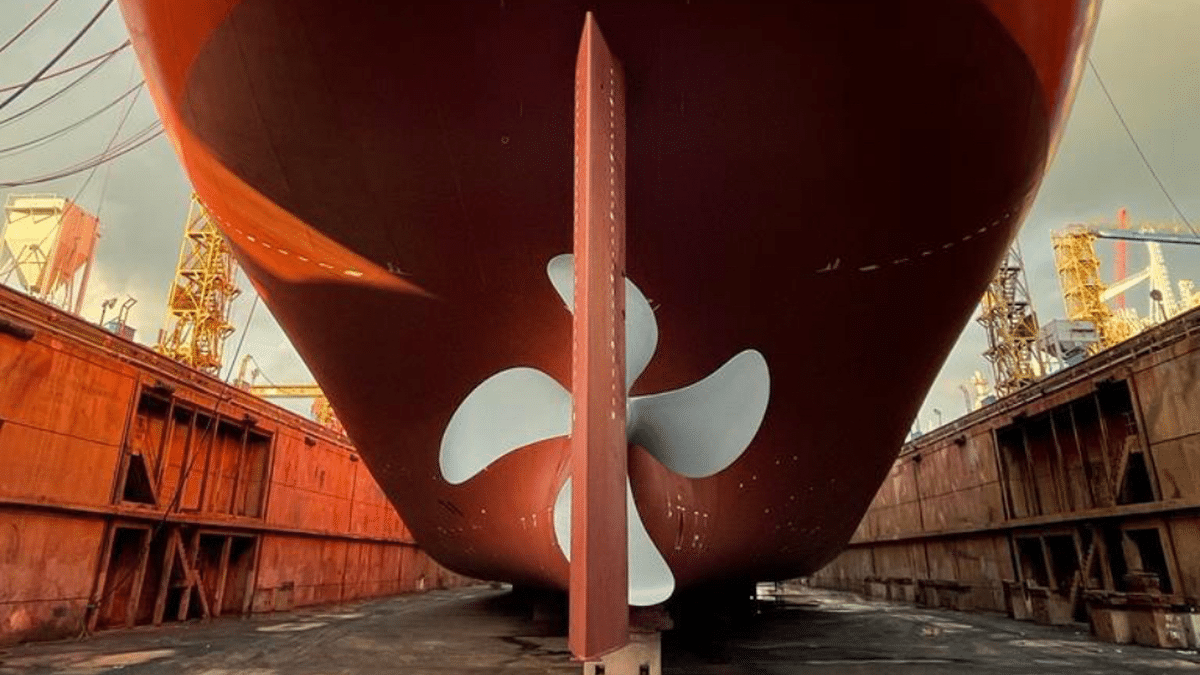

The specialised coating reduces mean surface roughness and the wet coefficient of friction significantly, according to data shared by Mr Gaier.

“You can use nylon brushes to clean and restore your propeller”

Before the coating was applied, the propeller’s surface roughness was gauged at Rt 200-225 µm and after coating Rt 200-225 µm, and the wet coefficient of friction was 0.775. After XGIT-Prop was applied, data showed less drag and a surface roughness of Rt 25-40 µm and a wet coefficient of friction of 0.25.

“If you have less surface roughness, you are going to have the water moving further through the surface and in a lower drag coefficient on the surface,” he explained.

Biocide free, XGIT-Prop could be applied to the propeller during a regular dry docking, said Mr Gaier, producing a 3-4% fuel savings and an ROI of about four months. A case study for a 30,000-dwt chemical tanker projected an annual fuel savings of US$98,000 and a three-month ROI.

The graphene-based propeller coating eliminates the need for propeller polishing. “When you are using a propeller coating, you are actively preventing fouling,” said Mr Gaier. Fouled propellers lose efficiency over time. Six months after polishing, a propeller could be fouled with 25% barnacles and 75% slime, resulting in a fuel penalty of 1%. After 12 months, this could increase to 45% barnacles and 55% slime and a 2% fuel penalty.

By contrast, an XGIT-Prop-coated propeller remains relatively clean, with a light slime coating of 10% at six months and 20% at 12 months.

“You can use nylon brushes to clean and restore your propeller to the original shape and you do not see that curve of propulsion efficiency loss over time”, concluded Mr Gaier.

Meanwhile, Berg Propulsion sales manager, energy and efficiency, Magnus Thorén, explained why slow steaming may not be the best choice for improving a ship’s fuel consumption and CII rating, and in fact may be “causing less efficient ships”. In noting the pressure on ship operators to reduce emissions to meet IMO environmental regulations, Mr Thorén said vessels designed originally for a fixed operational speed at 18 knots that are now slow steaming at 14 knots are less efficient and overpowered. “This same vessel will not be efficient when comparing it with a newbuild that is designed for 14 knots,” he said. “The propeller, with high rpm and low pitch, is not efficient. We cannot expect any fuel savings from slow steaming for most vessels with fixed rpm and a CPP,” he noted.

Slowing steaming the vessel will not help much if you have a fixed rpm but changing over to a combinator mode will actually save some fuel per nautical mile, he said. In the case of controllable pitch propellers, combinator mode adjusts the shaft speed and the propeller pitch simultaneously to achieve optimum propeller efficiency.

“Combinator mode will actually save some fuel per nautical mile”

After studying an operator’s fleet or ship, Berg can suggest several solutions to improve energy efficiency. These might involve optimising the propeller blades for the ship’s new operational profile or upgrades to the control system to allow for operation in the combinator mode or the network frequency stabiliser. Additionally, an upgrade to the control system to allow dynamic drive can provide optimum pitch and optimum rpm for the vessel.

“Typical fuel savings with all these upgrades for a vessel can range from 15% in higher speed up to more than 20% in lower speed. This is a quite substantial impact on the CII and fuel costs,” he concluded.

Both Mr Gaier and Mr Thorén were panellists on Riviera Maritime Media’s webinar, Optimising propellers for efficiency and CII compliance. Berg Propulsion was the premier partner for the webinar, which was produced as part of Marine Propulsion Webinar Week, in August.

Source for all charts, Riviera Maritime Media