Regal Rexnord™ Powertrain Solutions Marine Winch Design Simplifies Components by 58%

How Powertrain Solutions Simplified Marine Winch Design for an International Engineering Company

An international engineering technology company that designs unique, sustainable products needed help creating a marine winch. Marine winches are vital for lifting and retrieving remotely operated vehicles (ROVs) on ocean vessels. ROVs are small, unmanned robots used to explore the ocean floor. They are controlled by a crew from the ship’s surface using a joystick and equipped with cameras to send live video back to the vessel. These robots sometimes carry equipment for taking samples or running tests deep in the ocean. Due to their size and weight, ROVs need a strong winch system to safely lower them into the water and lift them back up.

The company found that designing a winch to meet all their needs was challenging. They had an initial idea but wanted a simpler, low-maintenance solution. That’s when they contacted Regal Rexnord’s Powertrain Solutions team through their website’s “Ask an Expert” feature. Together, they worked on a new design to meet the tough demands of marine work.

Challenges of the Marine Winch Design

There were two main challenges in designing the marine winch: physical and functional. Physically, the winch needed to resist corrosion from saltwater, have a simple design to reduce maintenance, and be small enough to fit in the limited space on the vessel. Functionally, the winch had to generate enough power to control, lift, and retrieve the ROV, as well as have a braking system that could hold the line in place when needed.

Solutions and Improvements

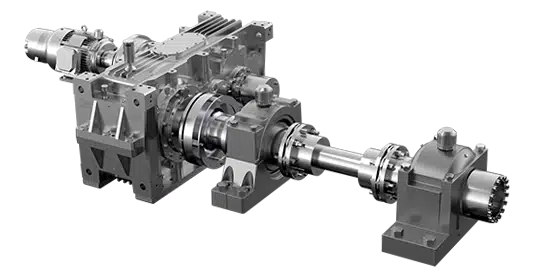

The Powertrain Solutions team partnered with the engineering company to improve their winch design. They simplified the design by removing seven unnecessary parts, including the synchronous belt, belt guard, and some bearings. By combining the motor, brake, and encoder into one Kollmorgen™ servo motor, they made the winch less complex and easier to maintain. The team also replaced the belt system with a more efficient braking solution.

These changes resulted in major benefits:

- 58% less complexity by eliminating unnecessary components.

- 32% cost reduction by removing parts and using a more efficient design.

- 13% lighter weight, making it easier to handle and install.

- Increased reliability and efficiency, with improved maintenance by eliminating parts prone to saltwater damage.

US Workboat Operators Need Industry Collaboration To Overcome Hesitancy In Low Emission Transition

The winch now uses a Kollmorgen servo motor and VFD (variable frequency drive) with a resistive load bank for braking. This system allows for dynamic braking by sending power to the resistor bank and static braking with an integrated brake inside the motor. By changing the way braking is done, the winch became smaller, cheaper, and more efficient. The motor braking system multiplied the force through the gearbox, allowing the customer to remove a roller bearing that was supporting the drum winder.

Cost Savings and Time Efficiency

Although the individual components in the new design were more expensive upfront, the overall cost of the winch system was much lower. The new design also made the winch easier and faster to assemble, cutting assembly time in half. Fewer parts meant reduced processing costs and less hassle in ordering and logistics. With one supplier for the whole system, the company could streamline their operations and reduce delays.

Other Benefits

- Faster braking and acceleration due to the servo motor and redundant braking system.

- Improved safety by eliminating the belt system, reducing the risk of load drops.

- Lower guarding costs because fewer parts needed protective covers.

The final winch design not only met the customer’s needs but exceeded them. Powertrain Solutions helped the company save money, reduce weight, and simplify their operations, all while improving the reliability and performance of the winch.

Powertrain Solutions continues to help companies achieve their goals by designing efficient, reliable systems tailored to each customer’s unique needs. Whether it’s a complex marine application or something else, Powertrain Solutions can optimize your system for better performance and lower costs.