Failed Rudder Indicator Fooled Pilot Into Running Aground

On April 9, 2022, the bulk carrier Hagen Oldendorff encountered a serious incident while navigating the narrow entrance channel at Port Hedland, Australia. The vessel ran aground due to a malfunction in its rudder angle indicator, which misled the pilot into believing there was a rudder failure. This incident highlights the critical importance of reliable navigational equipment and the potential consequences of technical failures in maritime operations.

Sequence of Events Leading to Grounding

The Hagen Oldendorff departed from the pier at Port Hedland around 12:45 AM, loaded with iron ore. The ship was making a steady seven knots as it moved through the dredged outer channel. However, within a tight timeframe of just three minutes, a series of events unfolded that would lead to the vessel running aground.

At 1:37:49 AM, the pilot and bridge team heard unusual clicking sounds from an electrical compartment. Suddenly, the rudder angle indicators went dark. At that moment, the ship began to swing to starboard at a rate of approximately four degrees per minute. In an attempt to regain control, the pilot ordered a port rudder command of 20 degrees and instructed the aft escort tug to pull the stern to starboard. He also directed the helmsman to use non-follow-up steering to execute the order.

By 1:38:10 AM, the pilot inaccurately reported a “rudder failure” to the tug’s master. Although the ship’s swing to starboard had been largely checked, the rudder remained at 20 degrees to port, causing the vessel to swing in the opposite direction. As the helmsman continued to apply steering commands, the rudder angle increased to 27 degrees to port. The pilot’s response, based on the false assumption of a rudder failure, led to further confusion and ineffective maneuvers. Despite attempts to counteract the swing, the ship ultimately ran aground at 1:40:34 AM, impacting the channel’s edge at a speed of about six knots.

Understanding Spade Rudders: Benefits, Materials, and Design Considerations

Investigation and Findings

Following the grounding, the ship’s master quickly identified that the rudder angle indicator was malfunctioning. He informed the pilot, and local steering controls were engaged. Additional assist tugs arrived, allowing the Hagen Oldendorff to transit to an anchorage for inspection. However, the damage had already been done. Flooding was discovered in the number one and two ballast tanks, causing the vessel to develop a trim by the head.

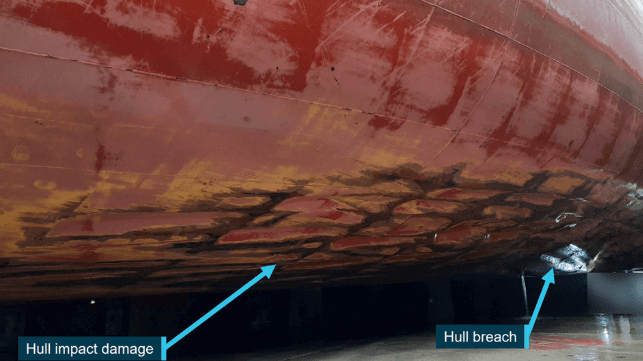

A dive inspection revealed two breaches in the hull, with extensive damage over a 150-foot section where the ship had made contact with the channel’s edge. Temporary repairs were conducted, and the ship later departed for China for drydocking.

The Australian Transport Safety Bureau (ATSB) conducted a post-accident inspection and found that a motor had shorted out in one of the six rudder angle indicators on the bridge. This failure tripped a breaker, causing all indicators to go dark simultaneously. The ATSB concluded that the bridge team did not consider the possibility of an indicator failure, leading to the erroneous assumption of a rudder malfunction.

Furthermore, the ATSB noted that while the Hagen Oldendorff met existing safety requirements, there were no regulations in place to protect the rudder angle indication systems from a single point of failure. They recommended that relevant authorities collaborate to address this critical issue, emphasizing the need for improved safety measures in maritime navigation systems.