MAN Introduces Second-Generation Common-Rail

New modular four-stroke injection system 2.2 builds on experience from previous CR

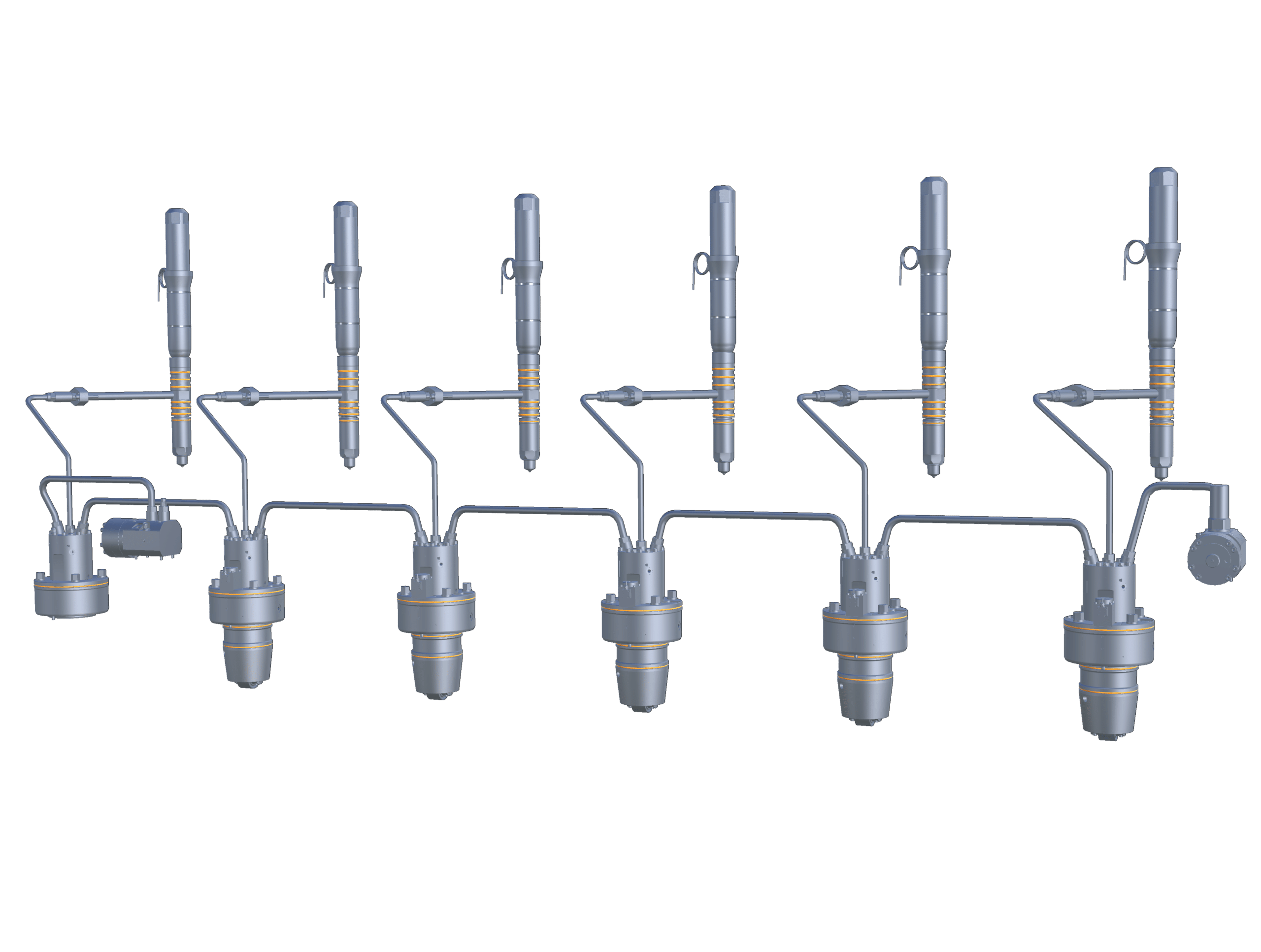

MAN Energy Solutions has unveiled its new CR 2.2 common rail fuel injection system, designed to enhance engine performance across its medium-speed, four-stroke portfolio. This advanced system, which will eventually replace the older CR 1.6 model, offers precise and flexible control over injection pressure, timing, and duration, resulting in optimized fuel consumption, emissions reduction, and overall engine efficiency.

A key aspect of the CR 2.2 system is MAN’s decision to bring the production entirely in-house, eliminating the reliance on external suppliers. Stefan Eefting, Senior Vice President and Head of MAN PrimeServ Germany, emphasized that this internal production process simplifies the system’s technical complexity and offers a modular design adaptable to various engine sizes. Drawing on over 17 years of operational experience from its predecessor, the CR 2.2 integrates valuable lessons learned to create a robust, market-ready solution.

New Sensor Listens To The Fuel For Optimum Engine Performance

The new system boasts significant improvements, such as a 38% increase in rail pressure and over a 33% extension in time-between-overhaul intervals for many components. Its redesigned high-pressure pump and new injector have been optimized for coherence and reliability, reducing the number of high-pressure connections by 35%, which significantly minimizes the risk of leakages and simplifies maintenance.

With additional benefits including reduced fuel consumption, lower emissions, and quieter engine operation, the CR 2.2 system offers improved performance and increased durability. Alexander Knafl, Senior Vice President, Head of Engineering R&D Four-Stroke, noted that the system has already successfully accumulated over 30,000 test hours and is compatible with a wide range of fuels, making it a key innovation for future engine development.