MOL and Petrobras signed a CTV Time Charter Contract

SeaLoader 2

March 06, 2024: TOKYO-Mitsui O.S.K. Lines, Ltd. (MOL; President & CEO: Takeshi Hashimoto) today announced that its wholly owned subsidiary, SeaLoading Holding AS (CEO: Yoshiro Kubo)(Note 1), which owns and operates cargo transfer vessels (CTVs) , has signed a charter contract for the CTV SeaLoader 2 with Petroleo Brasileiro S.A. (Petrobras), a Brazilian state-owned oil company. The two companies have also decided to enter into negotiations for a new CTV shipbuilding contract by the end of 2024.

SeaLoading started a CTV agreement with Petrobras for SeaLoader 2 on a trial period in January 2022, and successfully completed more than 30 crude oil offloading operations from Petrobras’ FPSOs located in the Santos Basin, Brazil, transferring the cargo to tankers – the trials involved vessels up to VLCC size. After the successful conclusion of the trial agreement, proving the CTV technology efficiency and reliability, the vessel was placed on a time charter contract in 2023 with Petrobras. Now SeaLoading has signed a memorandum of understanding (MoU) with Petrobras to start the negotiations for a newbuilding CTV by the end of 2024.

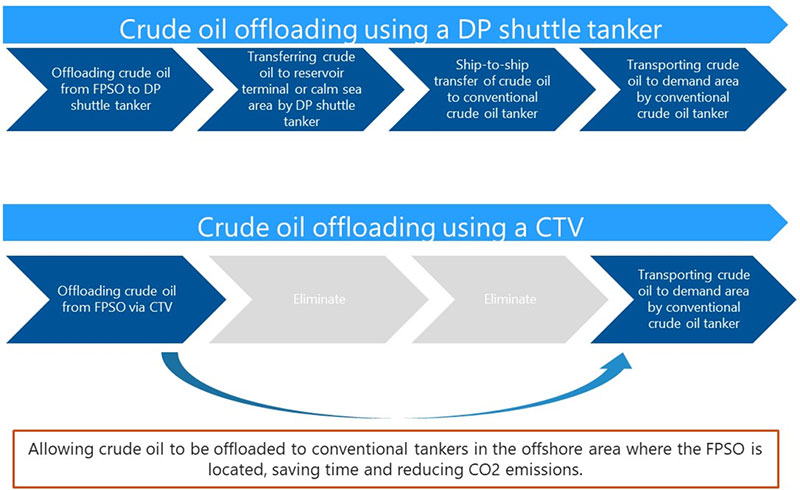

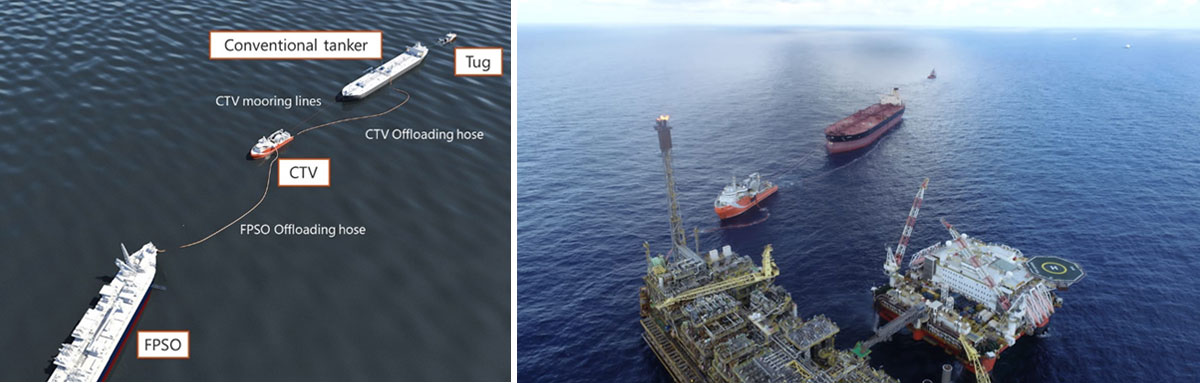

The crude oil produced from offshore fields by a floating production, storage & offloading system (FPSO)(Note 2) is usually transported to the demand area via crude oil tankers, which, in most cases, requires DP shuttle tankers(Note 3) with special cargo handling equipment firstly receive the crude oil and transport it to an oil storage terminal or calm waters where it can be offloaded (or transshipped), and then reloaded onto a crude oil tanker. In the case of CTV, the crude oil can be directly loaded from the FPSO to the crude oil tanker by connecting a CTV between an FPSO and the crude oil tanker. This dramatically increases the efficiency of crude oil logistics.

Currently, there are only 2 two CTVs in the world, all owned by SeaLoading, which holds the patent for the CTV technology.

[Comparison of Shuttle Tanker and CTV Crude Oil Supply Chains]

[Schematic diagram and photo of cargo handling with CTV]

The use of CTVs will also enable a significant reduction in CO2 emissions compared to the transfer of crude oil by DP shuttle tankers. Specifically, CTVs are expected to achieve a 60% reduction in CO2 emissions off the Brazilian coast compared to using a DP shuttle tanker for offloading in the Santos basin, Brazil and about 80% when it is used off the coast of Uruguay. (The reduction rate will vary depending on the actual CTV and the DP shuttle tanker’s loading/offloading, fuel consumption, sea conditions, and so on.)

The MOL Group is strengthening its collaboration with Petrobras and other oil majors, with the aim of further spreading the use of CTVs in the future, a move that can significantly reduce CO2 emissions and costs compared to conventional crude oil transfer by DP shuttle tankers, and will continue to improve efficiency and reduce environmental impact in the supply chain from crude oil production and storage to offloading.

(Note 1) SeaLoading

MOL acquired 100% of SeaLoading’s shares in 2022 after entering the CTV business in 2019.

| Head Office | Arendal, Norway |

|---|---|

| Established | 2014 |

| Representative | Yoshiro Kubo |

| Business | Own, market and operate 2 CTVs |

(Note 2) FPSO: Floating Production, Storage & Offloading Systems

Oil reservoir fluids extracted from deep-sea oil fields are brought into an FPSO and separated into crude oil and gas by processing equipment on deck. Treated crude oil is transferred to the cargo tanks in the FPSO’s hull, and regularly offloaded onto shuttle tankers. Treated gas is used as fuel for the FPSO. It is also transported to shore via pipeline or re-injected back into oil wells. This entire series of operations is performed aboard the FPSO. Many FPSOs are converted second-hand oil tankers. The mooring equipment, production equipment, offloading equipment, and so on are installed on the FPSO after hull reinforcement.

(Note 3) DP Shuttle tankers

Shuttle tankers transport crude oil from FPSOs or other offshore production facilities to onshore terminals. These tankers are equipped with dynamic positioning systems (which electronically control the ship’s maneuvering to maintain its position), offshore loading equipment mounted on the bow, and so on to ensure safe loading operations without anchoring, even under severe sea, weather, and tide conditions.