Riviera – News Content Hub

Engine manufacturers have introduced new units and completed benchmark products that enable workboats, tugs and harbour craft greater flexibility in terms of power, performance and emissions reductions.

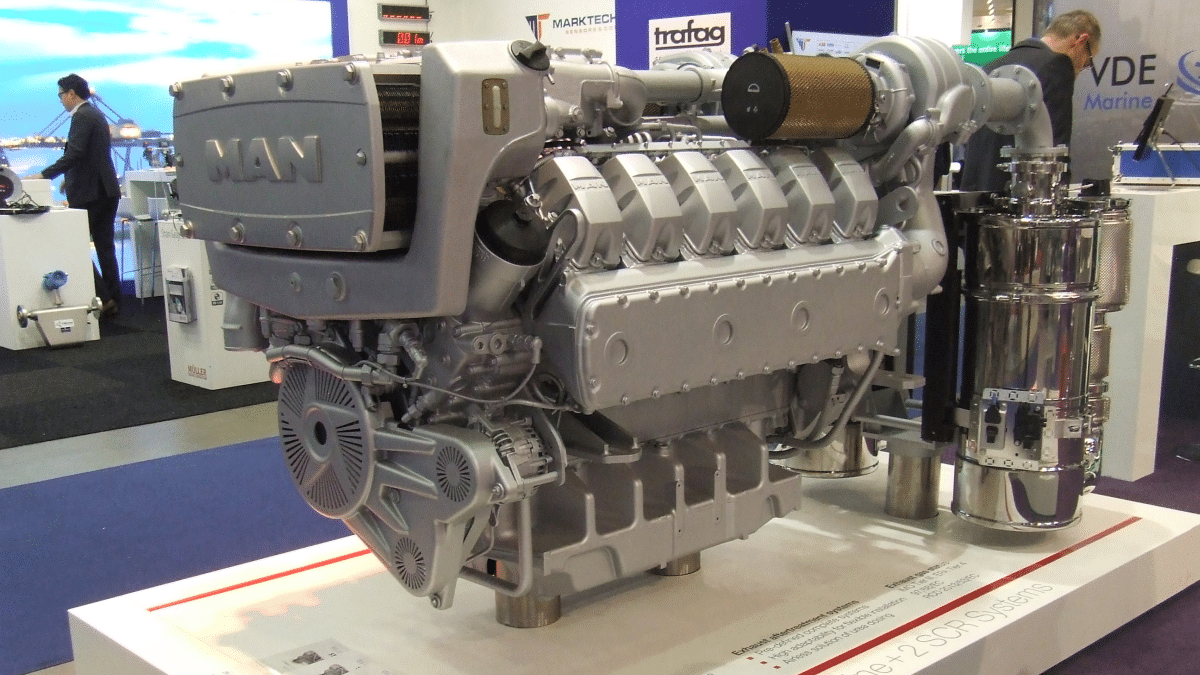

MAN Energy Solutions has developed a dual-fuel engine for fast workboats and small tugboats that runs on diesel and hydrogen. Its D2862 four-stroke engine has 12 cylinders in a V configuration, single cylinder heads, direct diesel and hydrogen injection into charge air and an exhaust aftertreatment system for IMO Tier III compliance.

A pair of these dual-fuel engines were installed into hydrogen-powered crew transfer vessel (CTV) Windcat Workboats Hydrocat 48, operating in Belgium. CMB.Tech retrofitted MAN ES D2862 LE428 engines with a hydrogen injection system, enabling an 80% reduction in conventional fuel use and emissions.

MAN ES’s D2862 V12 four-stroke engine weighs 2,270 kg and can produce 750 kW of power at 2,100 rpm. It has a stroke of 157 mm and a bore of 128 mm. It has a displacement of 24.3 litre and rated torque of 3,406 Nm.

MAN ES said the engine can run 4,000 hours per year at an average load up to 60%. There is a single turbocharger with charge air intercooler and wastegate, while the engine is seawater cooled by a rubber impeller pup or a two-circuit cooling system.

A representative of MAN UK distributor, PME Power Systems, told Riviera Maritime Media this range would be extended with V12 engines at lower power and running speeds for other workboat applications in the next few years.

Marine and Hazardous (M&H) Engines has shipped the first marine engines that comply with California Air Resource Board (CARB) Tier 4+DPF strict emissions standards for workboats.

“Our engines have twin turbochargers, exhaust gas recycling and optimised aftertreatment”

These nine-litre, six-cylinder diesel engines can produce 317 kW at 2,200 rpm, with a torque of 1,376 Nm and peak torque speed of 1,600 rpm.

M&H managing director, Barry McCooey, said these engines produce 99.8% less carbon monoxide, 99.8% less NOx and 99.8% less particulate matter than EU Stage I engines.

“Our engines are approved to meet CARB standards and the first two have arrived in California,” he said. “Our engines have twin turbochargers, exhaust gas recycling and optimised aftertreatment that includes DOC, SCR and diesel particulate filters.”

This range of ultra-low emissions engines includes diesel engines with displacement of 4.5 litres and 6.8 litres. Mr McCooey said engines with 14 to 18 litres displacement were under development. M&H 4.5-litre marine engines are rated at 130 kW at 2,200-2,400 rpm, while the 6.8-litre develops 170-224 kW at 2,400 rpm.

IMO Tier III options

AGCO Power has developed a new diesel engine with a power range of 155-201 kW. It features an aftertreatment system for compliance with IMO Tier III and EU Stage V emissions requirements.

UK-headquartered Mermaid Marine was the first to receive this new engine, in mid-June 2023. Mermaid sales executive, Julian Osborne, said production of these 74 LFEN-M engines started in August 2023. This four-stroke engine has a displacement of 7.4 litres and employs six in-line cylinders, common rail injection, turbocharger, air-to-water cooling, diesel oxidation catalyst (DOC) and selective catalytic reduction (SCR).

“There will also be a 4.9 litre in-line four-cylinder engine soon,” said Mr Osborne. “This will be going through prototype design and should be approved by the end of Q3 2023,” he said. DNV has already certified the 74 LFEN-M engine for use on harbour and fishing vessels and workboats.

Scania has expanded its range of engines for workboats and harbour vessels operating in emission control areas. It has added seven new engines that are compliant with IMO Tier III emissions standards, with power ratings of 250 to 450 kW.

These new engines have a higher compression rate than those compliant with IMO Tier II and come with SCR units to minimise NOx emissions from the exhaust. These are Scania DI-13 units, with power of 257 kW, 280 kW, 284 kW, 331 kW, 368 kW, 405 kW and 441 kW at 2,100 rpm.

They are available with heat exchangers or keel cooling systems and are type approved by classification societies ready for delivery H2 2023. The SCR units contain an exhaust routeing valve, enabling a bypass of the SCR to meet class requirements.

Hyundai Seasall has developed two new common-rail diesel engines, with IMO Tier III options for light-duty commercial workboats. The four-cylinder version achieves 149 kW and the V6 version develops 207 kW. There are stern-drive and shaft-drive gearbox options.

Hyundai Heavy Industries introduced its range of IMO Tier III engines after HD Hyundai Infracore acquired Doosan and rebranded the engines. This includes the DL08 six-cylinder engine with SCR for IMO Tier III compliance.

Japanese developments

IHI Power Systems has tested its first dual-fuel ammonia-diesel engines in Japan, in collaboration with NYK Line, Nihon Shipyard Co, Japan Engine Corp and ClassNK.

They completed a land-based test for the stable combustion of ammonia fuel in April 2023, achieving an 80% co-firing ratio. Their goal is to install these engines in a converted tugboat in 2024.

IHI Power Systems conducted operational tests at its Ota plant in the Gunma Prefecture on a 280 mm bore, four-stroke, ammonia-fuelled marine engine. Its latest trials included testing exhaust gas aftertreatment devices and fuel supply systems, confirming that emissions of di-nitrogen monoxide (N2O), which has a greenhouse effect about 300 times greater than CO2, and unburnt ammonia, were virtually zero.

Development, manufacture and shop trials of the Niigata four-stroke, ammonia-fuelled engines will follow and IHI anticipates they will be installed on a tug vessel in June 2024.