NYK and MTI Develop New Technology to Safely Transport “Green Steel”

Improving Steel Industry’s Environmental Impact and Helping Seafarers

On November 8, NYK Line (NYK) and MTI Co., Ltd. (MTI) introduced a new technology designed to make transporting reduced iron by bulk carrier safer and more efficient. Reduced iron is a cleaner alternative for making steel, using hydrogen instead of traditional carbon sources, which cuts down on carbon emissions. This innovation aims to make the steel industry more environmentally friendly and enhance working conditions for sailors.

How the Technology Works

1. Monitoring the Environment Inside the Ship’s Hold

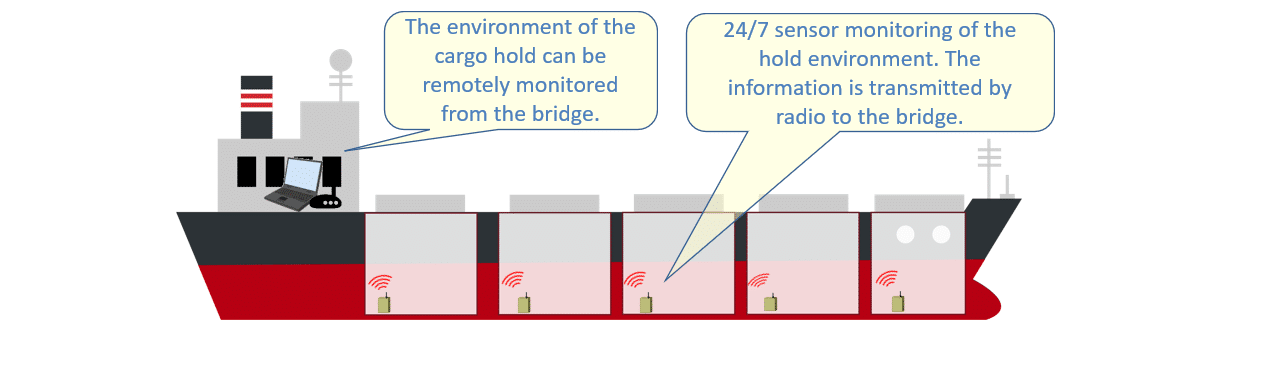

Using Internet of Things (IoT) technology, NYK and MTI have created a system that watches over the ship’s cargo in real-time. It measures important factors like temperature, humidity, and oxygen inside the holds. This way, potential dangers can be detected early, reducing the risk of accidents. Crew members no longer have to check the hold as often, making their jobs safer and helping prevent errors that could lead to accidents.

2. Predicting Conditions Inside the Hold

The new system can predict the conditions inside the ship’s hold during the journey. It uses advanced technology, including machine learning, to analyze the ship’s design, weather conditions, and the cargo’s initial temperature. This prediction helps make better decisions to ensure the cargo’s safety throughout the voyage.

3. Helping the Crew with Onboard Safety Decisions

Information collected by the system is displayed onboard to assist the crew. It shows real-time data on temperature, humidity, and air quality, helping the crew decide if it is safe to enter the hold or if any adjustments are needed, such as adjusting ventilation or injecting inert gas. This makes the cargo’s journey much safer and helps protect the crew.

4. Monitoring from Land for Extra Safety

The system doesn’t just work on the ship; it also lets experts on land keep an eye on things. Using satellite communication, the data can be viewed in real-time from an office. This way, the crew isn’t the only line of defense; experts on land can help guide the ship safely.

Why This Matters

Reduced iron is a key material for the steel industry to cut carbon emissions. It is made using hydrogen, not coke, which lowers greenhouse gas emissions. As a result, reduced iron is becoming more important for making environmentally friendly steel, also known as “green steel.” But transporting reduced iron comes with challenges, such as the risk of overheating, fires, or even explosions. This new technology makes it possible to move reduced iron safely, which supports a greener steel industry and protects the people working on the ships.

Ministry of Steel organizing an event Greening Steel: Pathway to Sustainability

NYK and MTI are making these advancements as part of the NYK Dry Bulk Division’s broader goals. They aim to go beyond just transporting goods and look for new ways to improve the shipping industry. This includes developing safer transport technologies and forming partnerships to achieve greener goals.

Other Innovations in NYK’s Strategy

Here are a few other steps NYK has taken to improve its shipping services:

- Solution Development: They recently tested a robot that cleans cargo holds and a new system to reduce ship movement when moored.

- Business Alliances: NYK has signed agreements to explore ship recycling and to work on future projects involving “bioship” technology.

- Technology Development: NYK successfully tested a new monitoring system using IoT sensors and is planning to build the first ship powered by biomass fuel.

The Importance of “Green Steel”

Reduced iron is sometimes called “green steel” because it helps cut down on carbon dioxide emissions, making it better for the environment. It avoids the use of traditional coke, which is carbon-based, and instead uses hydrogen. This shift is crucial for the steel industry, which is under pressure to reduce its carbon footprint and become more sustainable.