Understanding Spade Rudders: Benefits, Materials, and Design Considerations

A spade rudder is a modern innovation in marine engineering, predominantly utilized in contemporary sailing vessels and motor yachts. This rudder type is distinct from traditional designs due to its free-standing nature, connected solely to the hull via the rudder stock. This unique configuration endows spade rudders with enhanced manoeuvrability and responsiveness, key attributes prized by modern sailors.

The structure of a spade rudder is relatively straightforward yet highly effective. It consists of a rudder blade, which is the primary surface that interacts with water to steer the vessel, and a rudder stock, a robust shaft that connects the blade to the vessel’s hull. Unlike conventional rudders that are affixed to the keel or skeg, spade rudders are independent, allowing for greater freedom of movement. This design minimizes drag and improves the hydrodynamic efficiency, contributing to better overall performance.

Historically, the development of the spade rudder marks a significant advancement in naval architecture. Traditional rudders, often cumbersome and less responsive, were gradually replaced as spade rudders demonstrated superior handling characteristics. The adoption of spade rudders began in earnest in the mid-20th century, coinciding with advancements in materials science and hydrodynamic research. These rudders quickly became the preferred choice for performance-oriented vessels, where agility and precision are paramount.

Spade rudders are commonly found on a wide range of vessels, from high-performance racing yachts to luxurious motor yachts. Their versatility and effectiveness make them suitable for various applications, including leisure cruising, competitive sailing, and long-distance voyaging. The ability to execute sharp turns and maintain course stability under varying conditions underscores their popularity among sailors seeking both efficiency and control.

In essence, the spade rudder’s design and functionality represent a blend of simplicity and sophistication, offering a pivotal advantage in modern nautical endeavors. As technology and materials continue to evolve, the spade rudder remains a cornerstone of innovative marine design, ensuring vessels navigate with precision and confidence.

Components of Spade Rudder

A spade rudder is a free-standing rudder that is not supported by a keel or skeg, making it a critical component for steering in many vessels. Here are the main components of a spade rudder:

1. Rudder Blade

- Shape: The rudder blade is the primary surface that interacts with water to steer the vessel. It’s typically designed with a hydrodynamic foil shape to provide lift and minimize drag.

- Core: The interior of the rudder blade often has a lightweight core, such as foam or balsa wood, which provides shape and structure.

- Skin: The exterior of the rudder blade is typically made of strong materials like fiberglass, carbon fiber, or metal to withstand the forces exerted during operation.

2. Rudder Stock (Shaft)

- Material: The rudder stock is usually made of strong, corrosion-resistant materials such as stainless steel or aluminum.

- Function: It connects the rudder blade to the steering system inside the boat and transmits the steering forces.

3. Rudder Bearings

- Upper Bearing: Supports the top of the rudder stock, allowing it to rotate smoothly. It’s located where the stock passes through the hull.

- Lower Bearing: Provides additional support at the lower end of the rudder stock, reducing stress on the upper bearing and ensuring smoother operation.

- Materials: Bearings are usually made of materials like bronze, Delrin, or other engineered plastics that resist wear and corrosion.

4. Rudder Tube/Housing Wall Thickness

- Function: The rudder tube encloses the rudder stock and passes through the hull of the vessel, providing a sealed path to prevent water ingress.

- Material: It is usually made from fiberglass, composite materials, or metal.

5. Tiller or Steering Arm

- Tiller: A lever attached to the top of the rudder stock for manual steering. Common in smaller boats.

- Steering Arm: In larger boats with wheel steering, a steering arm connects to the rudder stock and is linked to the steering mechanism (like cables or hydraulics).

6. Quadrant or Lever

- Function: Converts the rotational motion of the steering wheel into lateral motion, which moves the rudder. It’s often connected to the rudder stock via the steering cables or hydraulic system.

- Material: Typically made of metal, often stainless steel or aluminum.

7. Gudgeons and Pintles (if applicable)

- Function: These are pivot points that support the rudder on some designs. However, in true spade rudders, these are generally not used since the rudder is unsupported except at the stock.

8. Sacrificial Anode

- Purpose: A zinc or aluminum anode is often attached to the rudder to prevent corrosion through galvanic action, particularly in saltwater environments.

9. Jumping Collar

Prevents Vertical Movement: The primary function of the jumping collar is to prevent the rudder stock from moving upwards. This is especially important in spade rudders, where the entire rudder is supported by the bearings and the rudder stock. It also Locks the Rudder in Position: It holds the rudder stock in a fixed vertical position, ensuring consistent and reliable steering.

These components work together to provide effective steering control, balancing the need for strength, durability, and hydrodynamic efficiency.

How to Design a Spade Rudder

Designing a spade rudder is a multifaceted process that requires meticulous attention to various factors such as the vessel’s size, intended use, and operating environment. The rudder’s shape and size play a critical role in determining its effectiveness. The rudder blade should be proportionate to the boat’s dimensions and capable of generating adequate lift and minimal drag. A well-designed spade rudder ensures enhanced maneuverability and stability, contributing to the overall performance of the vessel.

The type of rudder stock is another crucial element in the design. Typically made from high-strength materials like stainless steel or composites, the rudder stock must withstand substantial loads without compromising integrity. The selection of the rudder stock material should be based on factors like corrosion resistance, strength-to-weight ratio, and ease of maintenance. The method of attachment to the hull is equally important; it must ensure robust connectivity while allowing for smooth operation and minimal wear over time.

Modern design tools such as Computational Fluid Dynamics (CFD) have revolutionized the way spade rudders are designed. CFD simulations allow designers to model fluid flow around the rudder, enabling the optimization of its shape and performance. These simulations can help identify potential issues such as turbulence and cavitation, which can be mitigated through iterative design adjustments. The use of CFD and other advanced modeling tools can significantly enhance the efficiency and reliability of spade rudders.

Best practices in spade rudder design include conducting thorough load analyses and fatigue assessments to ensure long-term durability. It’s also advisable to incorporate feedback from real-world use cases and previous designs to refine and improve the rudder. Keeping abreast of the latest advancements in materials science and fluid dynamics can provide valuable insights and help in developing cutting-edge spade rudders.

Designing a spade rudder involves several key steps, focusing on hydrodynamics, structural integrity, and overall performance.

1. Understand the Requirements

- Vessel Type: The size and type of the vessel (sailboat, motor yacht, etc.) will dictate the rudder size and shape.

- Performance Needs: Consider whether you need more maneuverability, stability, or a balance between the two.

- Materials: Choose between materials like fiberglass, carbon fiber, or metals, depending on weight, strength, and cost requirements.

2. Hydrodynamic Design

- Rudder Shape: A spade rudder is typically a balanced or semi-balanced design with a foil shape for efficiency. Use an airfoil shape like NACA profiles for optimal lift and drag characteristics.

- Aspect Ratio: A higher aspect ratio (long and narrow) reduces drag and improves efficiency but can be structurally challenging.

- Chord Length and Thickness: Determine the chord length (front to back of the rudder) and thickness, aiming for a balance between structural integrity and hydrodynamic performance.

3. Structural Design

- Stock (Shaft): The rudder stock should be strong enough to withstand loads without bending. Common materials include stainless steel or aluminum. Calculate the required diameter based on the loads expected.

- Attachment to Hull: The rudder stock needs to be securely attached to the hull, typically through bearings and a support structure inside the hull.

4. Load Calculations

- Hydrodynamic Forces: Calculate the forces acting on the rudder at various speeds and angles to ensure the design can handle maximum loads.

- Torque and Bending Moments: Ensure the stock and rudder structure can withstand the torque and bending moments produced under load.

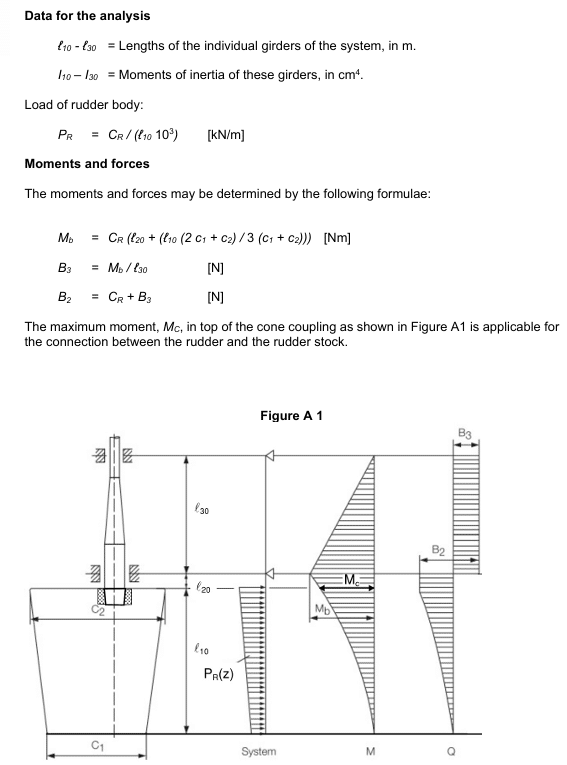

Here is guidelines from IACS S10. It indicates shear force and bending moment diagram based on rudder shape and stock dimension.

Materials Used in Spade Rudder Construction

The efficacy and longevity of a spade rudder are greatly influenced by the materials employed in its construction. Among the commonly utilized materials are aluminum, stainless steel, and various composites such as carbon fiber. Each of these materials presents unique characteristics that make them suitable for different applications, balancing factors such as strength, weight, corrosion resistance, and cost.

Aluminum stands out for its lightweight nature and excellent corrosion resistance, making it a popular choice for recreational and smaller commercial vessels. Its relatively low cost also contributes to its widespread use. However, aluminum’s strength is lower compared to other materials, which can be a limitation in demanding marine environments or for larger vessels requiring robust structural integrity.

Stainless steel or Carbon steel offers superior strength and durability, making it well-suited for larger commercial vessels and those operating in harsh marine conditions. Its high resistance to corrosion ensures longevity, even when exposed to saltwater environments. Nonetheless, stainless steel is significantly heavier and more expensive than aluminum, which can be a drawback for weight-sensitive applications.

Composites, particularly carbon fiber, are increasingly favored in the construction of spade rudders due to their exceptional strength-to-weight ratio. Carbon fiber composites are incredibly strong yet lightweight, which can enhance the performance and efficiency of the vessel. Additionally, these materials exhibit excellent fatigue resistance and are highly resistant to corrosion. The main downside is the high cost associated with carbon fiber, which can be prohibitive for some projects. Additionally, the manufacturing process for composites can be complex, requiring specialized knowledge and equipment.

Benefits of Using a Spade Rudder

Spade rudders have revolutionized maritime navigation, offering substantial advantages over traditional rudder designs. One of the most significant benefits is their free-standing design, which minimizes drag. This reduction in drag not only enhances a vessel’s speed but also contributes to improved fuel efficiency. Empirical data suggests that vessels equipped with spade rudders can experience up to a 10% increase in fuel efficiency, a crucial factor for both commercial and recreational vessels aiming to reduce operational costs.

Another primary advantage of spade rudders is their superior maneuverability. The design allows for more precise control, making it easier to navigate tight spaces or perform complex maneuvers. This is particularly beneficial for vessels operating in congested harbors or undertaking intricate docking procedures. Expert opinions in the field underscore that spade rudders provide a more responsive and agile handling experience, which can be a decisive factor in critical situations.

Additionally, spade rudders are often lighter than their traditional counterparts. The reduction in weight contributes to better overall performance and buoyancy. This weight advantage is due to the absence of a supporting structure, which is common in older rudder designs. The lighter weight not only improves speed but also reduces the strain on the vessel’s steering mechanism, enhancing the longevity of the steering system.